5. Risk assessment

Life stage

What is a life phase?

A machine passes through various phases in the course of its existence.

This begins with transport and ends with scrappage.

Between the two are the phases of standard operation,

repair and maintenance, and if applicable other phases.

Hazards can have differing effects on personnel in different life phases.

It may be therefore that measures that need to be instituted for certain hazards vary according to the life phase.

Example:

While a protective fence provides optimal protection for machine operators during standard operation,

maintenance staff need to enter the danger point to perform configuration work.

This requires a power supply.

However, no power supply is present when the protective equipment is open.

Approval functions exist for such situations that allow staff to perform certain machine movements even with the protective area in the open state,

thereby facilitating safe adjustment work.

What is this view useful for?

The selection of life phase during which the hazard occurs influences the choice of protective equipment.

The corresponding assignment is made on this page.

What are the next steps?

-

Determination of baseline risk

-

Determination of measures to minimise risk to an acceptable level.

Functions

Opens a dialogue window with a list of available life phases.

Opens a dialogue window with a list of available life phases.

New life phases can also be added by selecting

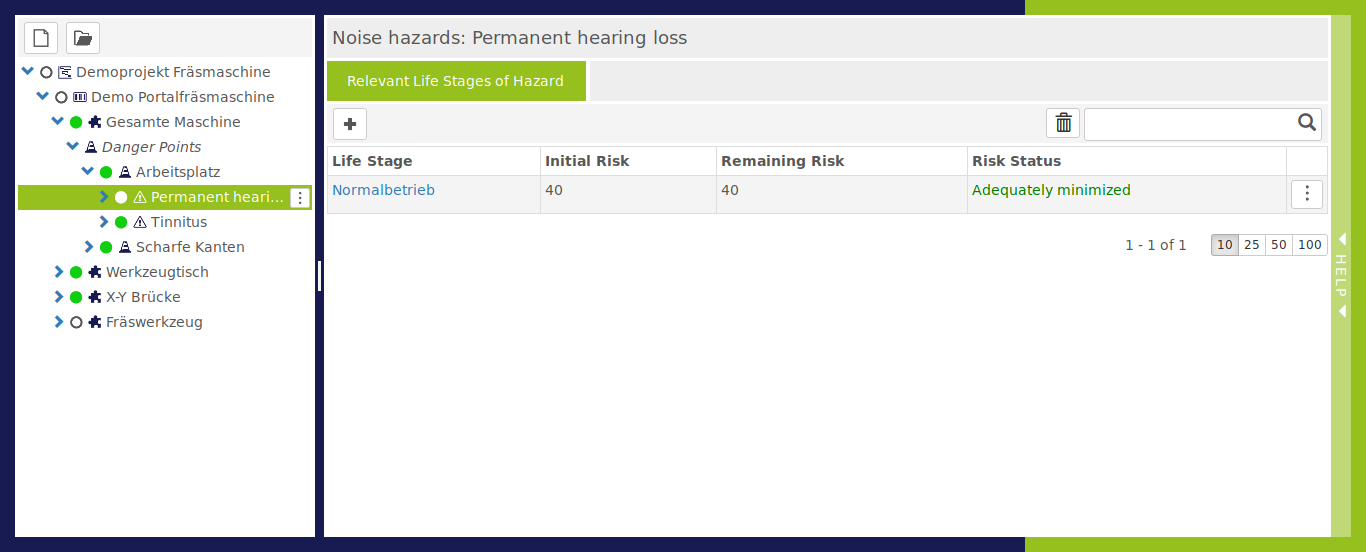

Risk assessment

What is a risk assessment?

The objective of risk assessment is to minimise identified hazards posed by a machine such that in the best case scenario, they are entirely eliminated.

However, the risk must be sufficiently minimised, i.e. reduced to an acceptable level.

Risk assessment encompasses the contents of the previous stages documented with CE-CON Safety.

E.g. the determination of limits or the identification of relevant hazards, which are part of product information.

What is this view useful for?

Danger points and associated hazards are identified here.

To facilitate the documentation of suitable counter measures at this stage to reduce risk,

the risk before and the residual risk after the determination of measures must be defined.

The final stages are implemented in this view.

What are the next steps?

-

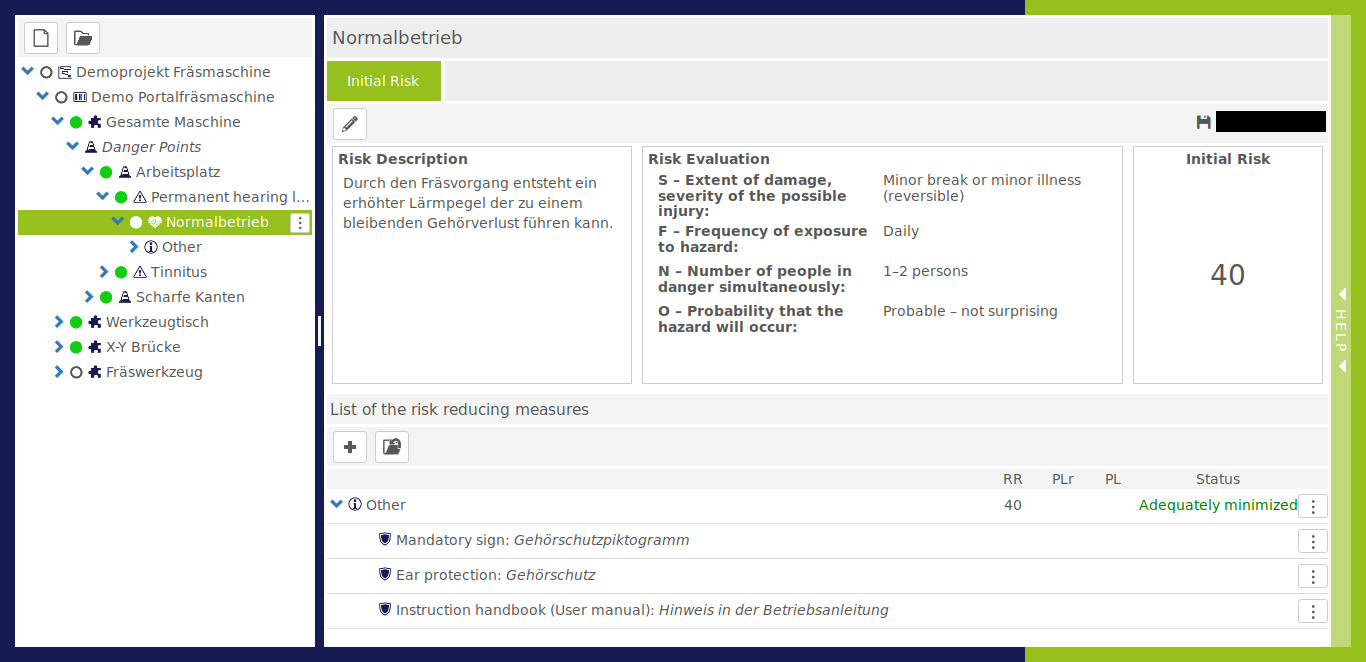

Description of situation or of hazardous event.

-

Classify baseline risk. The view includes selection fields for classifying the hazard. The baseline risk shown on the right results.

The procedure in determining the baseline risk involves defining the risk present WITHOUT any protective equipment.

-

Create or link protective measures.

When choosing the protective equipment, the 3-stage procedure must be considered. The initial stage encompasses intrinsically safe constructive measures, the second stage comprises supplementary protective measures (e.g. interlocking or optical guards) and the third stage includes all other measures (e.g. Personal Protective Equipment (PPE), pictograms, guidance information in operating instructions, etc.).

-

Open the selection list of protective measures using the + symbol.

-

Link: Here you can select existing protective measures.

Measures can also be applied in the context of other life stages, hazards or danger points.

Various filters can be used to restrict the possible selection of existing measures. For example, the possible selection can be limited to measures of the selected danger point.

When linking measures that, for example, also apply to other hazard points, it should be noted that future changes to the measure will affect all points where it is linked.

-

Create: New measures can be created from here using the + symbol. Select the required measure type from the list and fill in the input fields.

The inserted contents appear in the printout of the risk assessment!

-

-

-

Classify residual risk.

If one to x measures are added to a stage (constructive, functional, mechanical, other), the residual risk is determined.

-

Set the residual risk to "sufficiently minimised".

If the residual risk has been reduced to a minimum and no further measures are necessary, the residual risk is identified as sufficiently minimised.

If technical regulation protective equipment is assigned a Performance Level, the achieved PL must first be entered in the measure details (accessed via the 3-point menu) before the residual risk can be set to sufficiently minimised.

Measures

Special functions

- Deleting a measure can affect all components in whose context the measure is linked.

Measures can, for example, be linked in several danger points or hazards.. Deleting the measure would affect all components. You initiate the deletion from a particular perspective, in which it is clear in which context (life phase; hazard; point of danger) you want to remove the task. Depending on whether the task is linked with other components, you are offered various options for deleting or unlinking links.

Measure details

What is this view useful for?

In this view, you can view and edit the details stored for the measure.

You can also access measure templates that have already been created.

Relevant (harmonised) standards

What is this view useful for?

The manner of developing special measures is described in harmonised standards.

Here it is possible to factor in supplementary standards that render assistance for the selected measure.

Example:

The protective fencing measure is described in detail in EN ISO 13857.

Directives define the minimum requirements associated with products.

These are listed in Annex I of the machinery directive.

Standards set out in real terms how precisely these requirements can be implemented.

Harmonised standards are standards listed in the Official Journal of the EC.

These are viewed with the “presumption of conformity”.

This means that by implementing the content of standards, compliance with the requirements of the directive can be assumed.

If you add further standards to the list as relevant,

the directives listed here will also be printed on the declaration of conformity.

Risk assessment systems

Risk assessment system according to the Hazard Rating Numbers procedure.

For the quantitative determination of the risk levels of hazards the procedure described below is followed. The evaluation is performed separately for every hazardous situation. For a better overview, an overall risk factor is calculated. The result illustrates the level of risk with factors. The higher the number the higher is the risk found, the lowest corresponds to 0. The following classifications serve the determination of the individual parameters:

| S - extent of damage, severity of possible injury | |

|---|---|

| Scrape / Bruise / Contusion / Hematoma (first aid treatment) | 0,1 |

| Cut, minor injury (accident insurance consultant treatment) | 0,5 |

| Break of minor bone or minor illness (temporary) | 2 |

| Break of major bone or major illness (temporary) | 4 |

| Loss of one limb, eye, hearing (permanent) | 6 |

| Loss of 1 limb, eye (permanent) | 6 |

| Loss of two limbs or eyes (permanent) | 10 |

| death | 15 |

| F - frequency of hazard exposure | |

|---|---|

| Annual | 0.5 |

| Monthly | 1 |

| Weekly | 1.5 |

| Daily | 2.5 |

| Hourly | 4 |

| Constantly | 5 |

| N - Number of persons simultaneously exposed to the hazard | |

|---|---|

| 1-2 persons | 1 |

| 3-7 persons | 2 |

| 8-15 persons | 4 |

| 16-50 persons | 8 |

| > 50 persons | 12 |

| O - probability of occurrence of the hazard | |

|---|---|

| Nearly impossible - possible under extreme circumstances | 0.033 |

| Very improbable - though imaginable | 1 |

| Improbable - but could happen | 1.5 |

| Possible - though unusual | 2 |

| Maybe - can happen | 5 |

| Probable - not surprising | 8 |

| Very probable - to be expected | 10 |

| Certain - no doubt | 15 |

On the basis of the decision criteria, the level of risk is quantified as follows:

Risk ( R ) = S - F - N - O

The calculated risk values can be interpreted as follows:

| 0 - 5 | Negotiable risk - remaining risk is acceptable |

| 6 - 50 | Risk low, but exists – risk should be reduced further if possible |

| 51 - 500 | High risk - must be reduced |

| > 500 | Unacceptable risk - must be reduced in any case |

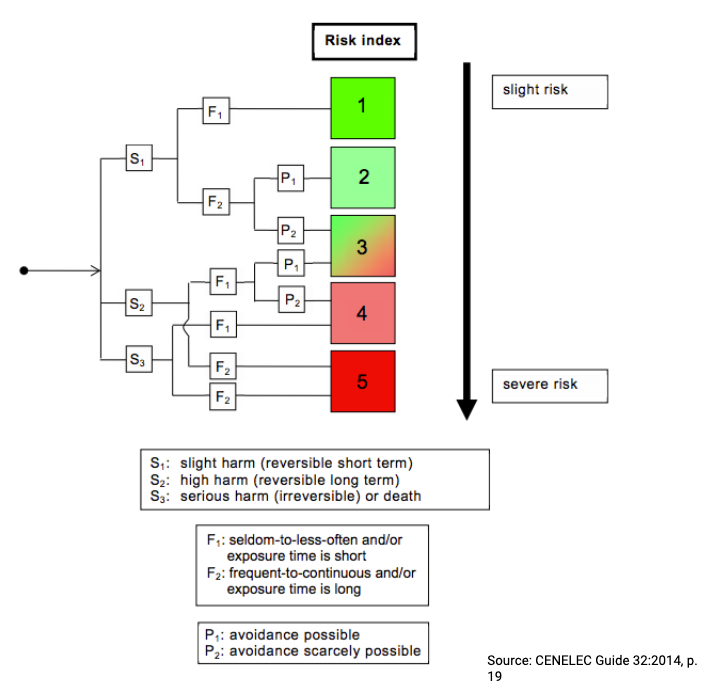

Risk assessment system according to CENELEC guide 32:2014

| Damage extent | Frequency of hazard exposure | Damage prevention/limitation | Risk |

|---|---|---|---|

| S1: slight harm (reversible in the short term) | F1: seldom-to-less-often and/or exposure time is short | 1 | |

| S1: slight harm (reversible in the short term) | F2: frequent to continuous and/or exposure time is long | P1: Avoidance possible | 2 |

| S1: Low damage (reversible in the short term) | F2: frequent to continuous and/or exposure time is long | P2: Avoidance scarcely possible | 3 |

| S2: High damage (reversible in the long term) | F1: seldom-to-less-often and/or exposure time is short | P1: Avoidance possible | 3 |

| S2: High damage (long-term reversible) | F1: seldom-to-less-often and/or exposure time is short | P2: Avoidance scarcely possible | 4 |

| S2: High harm (long-term reversible) | F2: frequent to continuous and/or exposure time is long | 5 | |

| S3: Severe harm (irreversible) or death | F1: seldom-to-less-often and/or exposure time is short | 4 | |

| S3: Serious harm (irreversible) or death | F2: frequent to continuous and/or exposure time is long | 5 |